Backflow testing is essential for irrigation systems to safeguard potable water from contamination and comply with regulatory standards. It prevents backpressure and back-siphonage, which can introduce harmful chemicals and pathogens into drinking supplies. Irrigation systems often use chemicals like pesticides and fertilizers, making them particularly vulnerable. Regular testing of backflow prevention devices like pressure vacuum breakers is vital to maintain functionality and water quality. Failure to perform testing could lead to health risks, environmental damage, and legal penalties. Certified professionals conduct these tests to guarantee accuracy and safety compliance. There’s more to uncover about maintaining safe water systems.

Understanding Backflow in Irrigation

In the domain of irrigation systems, understanding backflow is vital for maintaining water safety and system efficiency. Backflow occurs when the normal flow of water reverses, potentially allowing contaminants to enter the potable water supply. This situation arises due to changes in pressure within the irrigation system or the connected public water supply. There are two primary types of backflow: backpressure and back-siphonage. Backpressure is caused when the downstream pressure exceeds the supply pressure, whereas back-siphonage results from negative pressure in the supply line.

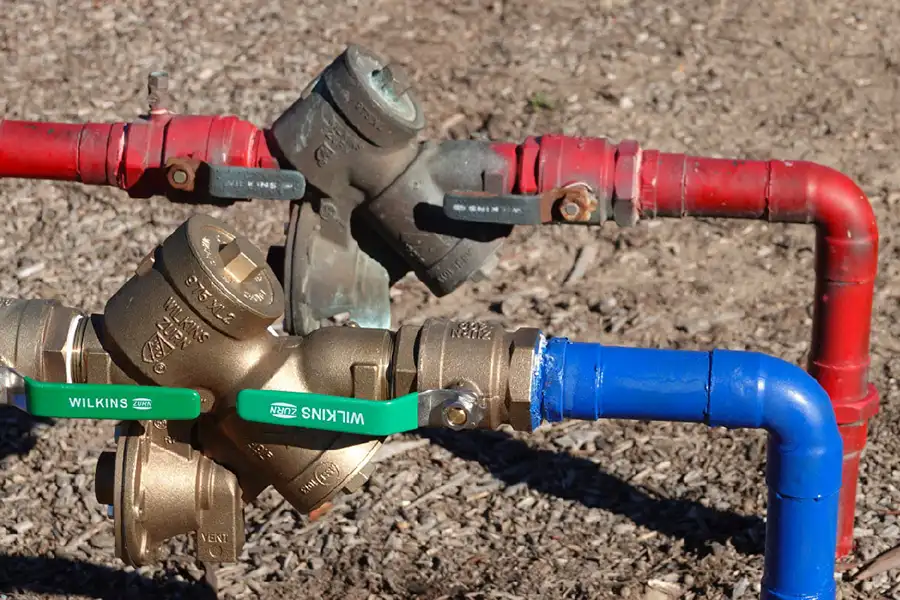

Irrigation systems are particularly vulnerable to backflow due to their direct connection to water supplies and frequent use of fertilizers and pesticides. These chemicals, if introduced into a potable water system, pose significant contamination risks. Preventing backflow necessitates installing backflow prevention devices, such as pressure vacuum breakers, double-check valves, and reduced pressure zone assemblies. Each device is designed to block the reverse flow of water, thereby safeguarding water quality.

Regular backflow testing guarantees these devices function correctly, maintaining the integrity of both irrigation and potable systems. Understanding and managing backflow is vital for anyone responsible for irrigation systems, emphasizing the importance of compliance with local regulations and standards.

Health Risks of Contaminated Water

Contaminated water poses significant health risks that can affect entire communities. When irrigation systems experience backflow, contaminants such as pesticides, fertilizers, and pathogens can enter the potable water supply. This scenario is particularly dangerous because these substances can lead to severe health issues, including gastrointestinal illnesses, neurological disorders, and even long-term chronic conditions. The presence of harmful bacteria like E. coli or viruses can result in outbreaks of diseases, impacting public health considerably.

To understand the gravity of these risks, one must consider the pathways through which contaminants infiltrate water systems. Backflow occurs when the pressure in the irrigation system exceeds the pressure in the potable water system, causing a reverse flow. This reverse flow can introduce various pollutants into drinking water, necessitating immediate preventive measures.

Regular backflow testing is essential as it guarantees that backflow prevention devices function correctly, thereby safeguarding the water supply from potential contamination. By maintaining rigorous testing protocols, communities can prevent health crises and protect their populations. Through proactive measures, individuals can mitigate the risks associated with contaminated water, ensuring a safe and healthy environment for all.

Environmental Impact Considerations

Backflow testing for irrigation systems isn’t just critical for human health but also plays a significant role in environmental protection. Contaminated water from irrigation systems can enter natural water bodies, introducing harmful chemicals and pathogens into ecosystems. This contamination disrupts aquatic life, affects biodiversity, and degrades water quality. Backflow prevention devices, consequently, act as essential safeguards, guaranteeing that pollutants like fertilizers and pesticides don’t seep from irrigation systems into local rivers, lakes, and groundwater.

Understanding how backflow testing contributes to this protection involves recognizing the flow dynamics of water systems. Irrigation systems often operate under variable pressure conditions, making them susceptible to backflow events. Without proper testing, these systems can malfunction, allowing contaminated water to reverse its flow. This poses a threat not just locally but downstream as well, affecting interconnected water systems and regional ecological balance.

Regular backflow testing guarantees that prevention devices function at their best, reducing the risk of environmental degradation. It safeguards habitats by maintaining clean, uncontaminated water sources. For those invested in environmental stewardship, understanding and implementing rigorous backflow testing protocols is essential. This proactive approach not only preserves ecological integrity but also aligns with sustainable water management practices.

Regulatory Compliance Requirements

Effective regulatory compliance is essential for guaranteeing the safety and functionality of irrigation systems. Regulatory requirements mandate regular backflow testing to prevent contamination of potable water supplies. These regulations, often established by local, state, or federal agencies, dictate the frequency and methods of testing, aiming to maintain public health standards. Compliance with these regulations isn’t just a legal obligation but a vital step in safeguarding community health.

Irrigation systems can pose significant risks if backflow prevention measures aren’t strictly adhered to. Contaminants from pesticides, fertilizers, and other chemicals can enter the water supply if backflow prevention devices fail or aren’t properly tested. Authorities require documentation of testing results to verify that the systems meet safety standards. Non-compliance can lead to severe penalties, including fines and legal actions, highlighting the importance of adhering to these regulations.

Professionals conducting the testing must be certified and follow strict protocols, guaranteeing that all components of backflow prevention devices function correctly. Understanding and meeting these regulatory compliance requirements helps protect not just the water supply but also the integrity of the irrigation systems themselves. This proactive approach minimizes risks and guarantees long-term system efficiency.

Steps in Backflow Testing Process

Knowledge of the backflow testing procedure is fundamental to the maintenance of irrigation systems and adherence to regulatory standards. First, a certified technician inspects the irrigation system to identify the type of backflow prevention device installed. This initial step is vital as it determines the specific testing procedures and equipment needed. Next, the water supply is shut off to prevent any potential contamination during the test. The technician then attaches test gauges to the device’s test cocks, ensuring accurate measurement of pressure differences across the device’s valves.

Once the equipment is set up, the technician opens the test cocks and records pressure readings. These readings are compared against acceptable thresholds to verify the device’s integrity and functionality. If the device fails to meet the required standards, it is either repaired or replaced to maintain compliance and safety. Finally, the technician restores the water supply and documents the test results, providing a thorough record for regulatory compliance and future reference. This meticulous process not only protects water quality but also reinforces the reliability of the irrigation system, safeguarding both public health and environmental integrity.